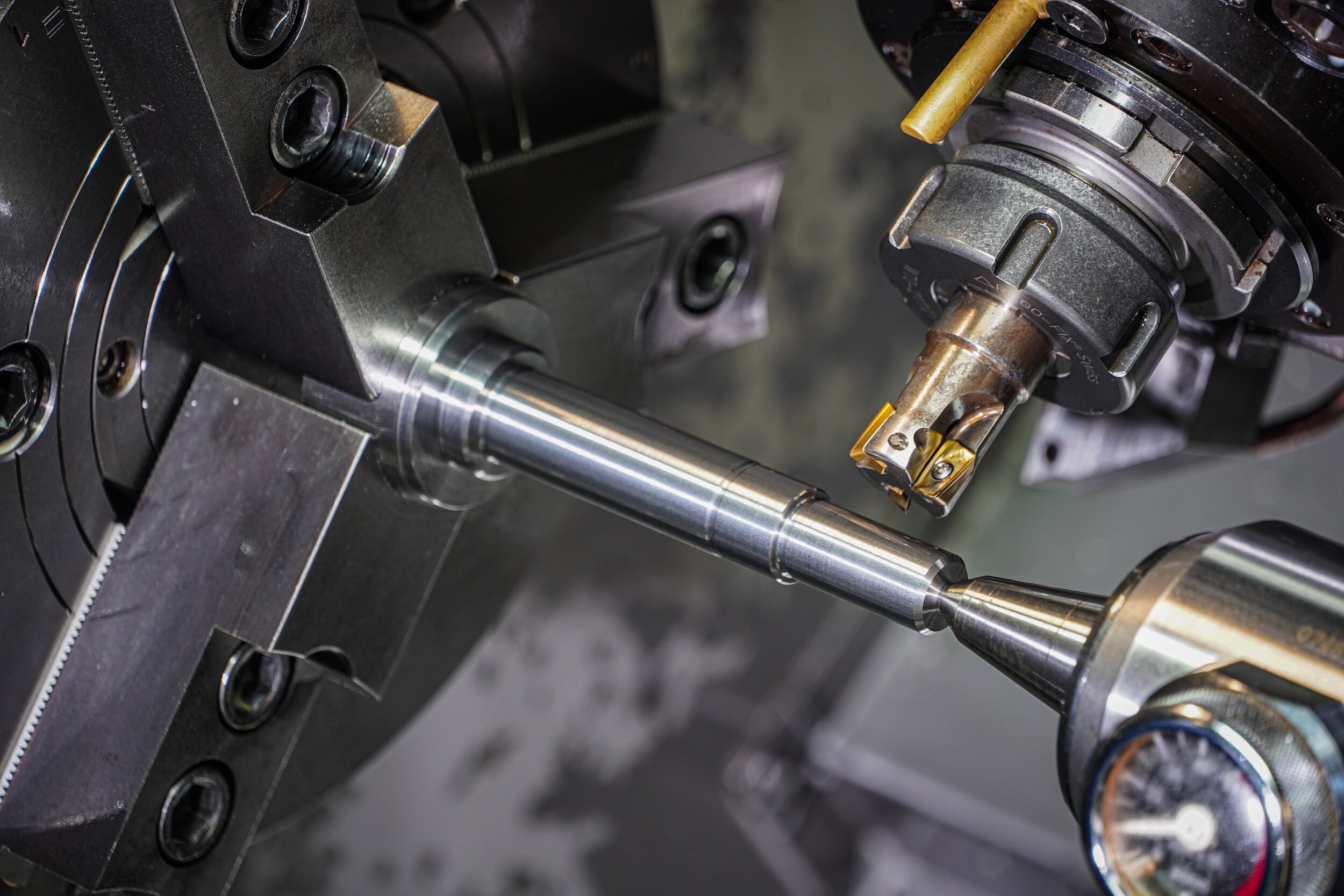

Machine Tending

Atgervi brings extensive expertise in robotic machine tending that covers a wide spectrum from handling small medical components to managing large industrial assemblies, and interfacing form simple lathes to complex 9-axis machining centers. Whether it's low-mix high-volume or high-mix low-volume scenarios, Atgervi is adept at meeting diverse needs.

Here are some examples of machine tending:

Single robot tending 3 lathes

Vision-guided systems for locating parts on conveyors or incoming part pallets

RoboDrill tending and integration

Let me elaborate on an intriguing machine tending system: imagine a setup where a robot is positioned between two vertical machining centers, allowing for both manual operation of the mills and autonomous robot operation. From the main control panel, operators can select which mill will operate automatically or manually.The robots are equipped with multiple gripper finger setups, enabling them to handle a wide variety of parts. Using a HMI (Human-Machine Interface), operators can choose the gripper type and finger selection, along with the programs to run for loading the mill.

Moreover, this system offers the flexibility for manual setup of the mills while robotic operation is ongoing. Area scanners are employed for access control, ensuring safety by reducing the robot's speed when an operator enters the restricted space. This feature enables operators to set up the system or run low-volume parts while the robot handles higher-volume production.

Furthermore, the system boasts large part drawers with changeable inserts for different-sized part blanks, facilitating unattended overnight operation. This comprehensive setup maximizes efficiency and productivity while ensuring operational flexibility to meet various production needs.